|

|

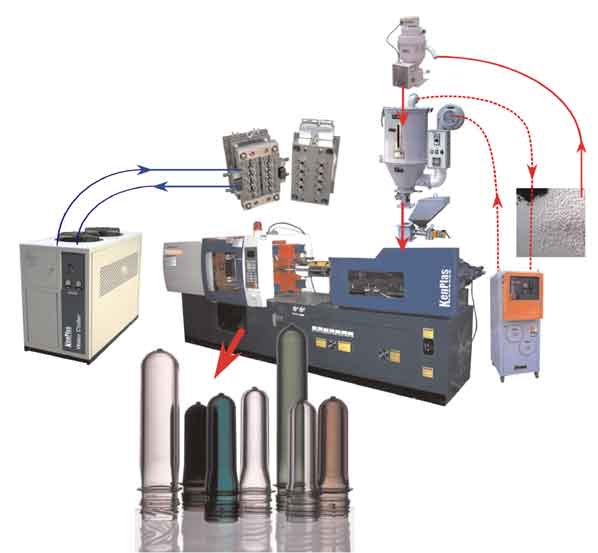

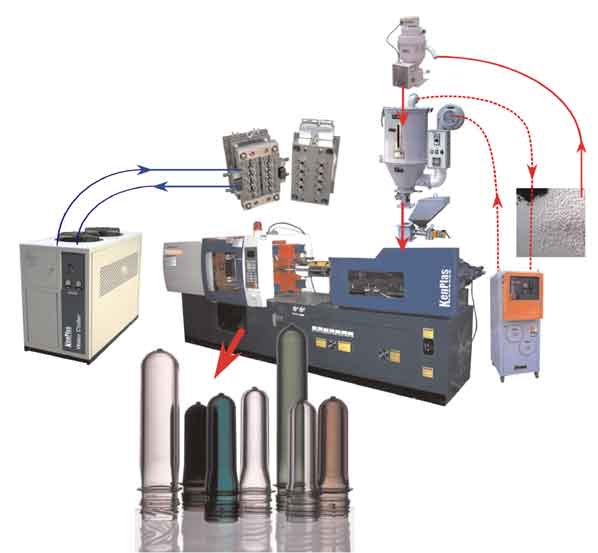

PET Preform Injection Molding

|

PET Preform Processing: PET Preform Processing:

|

|

Solution

|

|

|

|

Drying and Dehumidifying of PET

|

|

PET is a kind of moisture absorption plastics, usually its water

content is about 0.05%. To get perfect PET preform (transparency and

physical performance), also to enhance molding efficiency, the water

content of PET resin should be <=0.005%. Therefore necessary drying

of PET is required. The common drying methods:

- By oven:

A kind of outdated and laborious drying method. Oven is apart from

injection machine, dried PET is moved into the hopper of injection

machine manually, and un-dried PET is moved into oven manually

too.

As LVPET may get damp and caking while drying, only oven drying

method can be used for LVPET so that it can be turned over for 2

to 3 times during drying. The thickness of PET in the trays can be

about 50mm. If dried material is not used up, set oven's working

temperature to 1100C to keep it warm. PET should not be stayed in

oven for more than 8 hours, or it will deteriorate. Cooled

material should be dried again.

For LVPET, luster will appear when it is being dried. And the

luster will disappear when drying finished.

- By

Hopper Dryer

Most common and economical method to dry PET. If works together

with autoloader, PET will be loaded into hopper dryer and dried

continuously and automatically.

- By

Dehumidifier

Efficient but costly drying method, works together with hopper

dryer and autoloader. It dries PET in a closed loop system to

reach dew-point of at least -320C,

thus to exhibit the optimum physical performance and surface

finish of PET products.

|

|

Drying Temperature Drying target is to get

moisture level <=0.005% (at the same time, AA level should be strictly

controlledto avoid peculiar smell in the drink) The best drying

temperature and time are decided by IV value of PET resin. But

generally speaking, it should be 150~ 1700C

for about 4 hours. If dried PET contact air with relative humidity 35~40% for 12 minutes,

it's moisture content will reach 0.005%.

Long-time drying will reduce its IV value. So it is better to

shorten drying time. Drying time should not exceed 7~8 hours. |

|

Cooling of Preform Mold

|

|

Cooling of preform mold is also very important. It affects preform's

quality directly. The temperature of cooling water should be 15~200C,

and the pressure of cooling water should be around 5Bar.

Water chiller is suggested. |

|

Mold Temperature

|

|

For injection machine, temperature of nozzle and front zone should

be about 2800C, and middle zone around 2820C,

rear zone around 2750C. The temperature of hot runner in

preform mold should be around 2700C. These temperature

vary a little bit with IMM, preform's design and weight, mold's

structure and cooling, etc. |

|

Catalogue

Download |

|

|

Plastics Projects

Plastics Projects PET Preform/Bottle Project

PET Preform/Bottle Project PET Preform Processing:

PET Preform Processing: