|

|

Mould Sweat DehumidifierH.S.Code: 8419399090

|

SMD

series mould sweat dehumidifiers are designed to remove the

moisture sweat from condensing on the mould surface. Forming of

moisture sweat on the mould surface is due to the use of chilled

water for reducing the moulding cycle time, particularly while

moulding of the PET preforms. To bring about the moisture sweat

on the mould surface is because the mould surface temperature is

lower than the dew point temperature of surrounding air, thus

the water vapor comes into being, then causes corrosion of mould

and effects quality of moulding parts as well as production

efficiencies. This series of machine uses honeycomb rotor to

carry out dehumidifying function, which generates a dry airflow

with dew point ranging from 0~100C,

and ensures the surrounding air of mould remaining in a low

dewpoint temperature. It provides constant low dewpoint

surrounding air to the mould surface all year round without

being influenced by the change of seasons. SMD

series mould sweat dehumidifiers are designed to remove the

moisture sweat from condensing on the mould surface. Forming of

moisture sweat on the mould surface is due to the use of chilled

water for reducing the moulding cycle time, particularly while

moulding of the PET preforms. To bring about the moisture sweat

on the mould surface is because the mould surface temperature is

lower than the dew point temperature of surrounding air, thus

the water vapor comes into being, then causes corrosion of mould

and effects quality of moulding parts as well as production

efficiencies. This series of machine uses honeycomb rotor to

carry out dehumidifying function, which generates a dry airflow

with dew point ranging from 0~100C,

and ensures the surrounding air of mould remaining in a low

dewpoint temperature. It provides constant low dewpoint

surrounding air to the mould surface all year round without

being influenced by the change of seasons. |

|

Design Feature |

- Accurate control and display of regenerative temperature by

using PID control.

- Honeycomb rotor is used to ensure constant air dehumidifying

effect.

- Microprocessor board is fitted to indicate machine running

status and to diagnose malfunction.

- Motor overload and phase reverse alarm functions are included.

- Return air cooling and filtering are included.

- Under normal state and atmospheric conditions, the humidity

content of air can be controlled exactly all year round.

- Inhibits corrosion and prolongs service life of the mould, and

yet reduces moulding cycle time.

- Air temperature generated by this series of machine is about 300C,

this ensures moisture condensation in the moulding area will not

occur on the view window of the moulding machine.

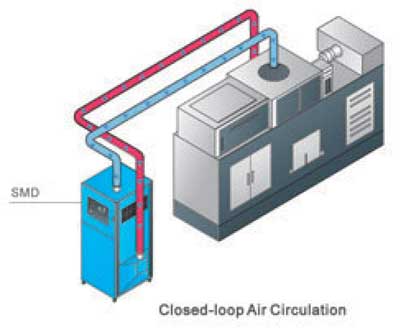

- Supplied as standard, a return air collector is used to collect

return air from the moulding area back to this machine and to form a

close-loop air circulation, which is particularly practical in

tropical climate.

- Dew-point monitor can be fitted as option to detect dry air

quality.

- Upon request, it can be built to comply with worldwide

electrical safety standards (e.g. CE, UL, CSA, JIS etc).

|

|

Specification |

|

Model |

|

Process Air Flow (m3/h) |

500 |

1000 |

1500 |

2000 |

|

Process Blower (Kw) |

0.75 |

1.5 |

1.5 |

3.0 |

|

Regeneration Heater (Kw) |

4 |

7.2 |

15 |

24 |

|

Dew Point (0C) |

-10 |

-10 |

-10 |

-10 |

|

Cooling Water Flow (L/min) |

50 |

50 |

100 |

100 |

|

Cooling Water Pressure |

3~5 Bar |

|

Dimension (LxWxH, cm) |

173x80x70 |

178x98x81 |

204x164x108 |

204x223x141 |

|

Weight (kg) |

260 |

335 |

350 |

450 |

|

|

Close-loop Installation

|

|

|

|

|

Plastics Machinery

Plastics Machinery SMD

series mould sweat dehumidifiers are designed to remove the

moisture sweat from condensing on the mould surface. Forming of

moisture sweat on the mould surface is due to the use of chilled

water for reducing the moulding cycle time, particularly while

moulding of the PET preforms. To bring about the moisture sweat

on the mould surface is because the mould surface temperature is

lower than the dew point temperature of surrounding air, thus

the water vapor comes into being, then causes corrosion of mould

and effects quality of moulding parts as well as production

efficiencies. This series of machine uses honeycomb rotor to

carry out dehumidifying function, which generates a dry airflow

with dew point ranging from 0~100C,

and ensures the surrounding air of mould remaining in a low

dewpoint temperature. It provides constant low dewpoint

surrounding air to the mould surface all year round without

being influenced by the change of seasons.

SMD

series mould sweat dehumidifiers are designed to remove the

moisture sweat from condensing on the mould surface. Forming of

moisture sweat on the mould surface is due to the use of chilled

water for reducing the moulding cycle time, particularly while

moulding of the PET preforms. To bring about the moisture sweat

on the mould surface is because the mould surface temperature is

lower than the dew point temperature of surrounding air, thus

the water vapor comes into being, then causes corrosion of mould

and effects quality of moulding parts as well as production

efficiencies. This series of machine uses honeycomb rotor to

carry out dehumidifying function, which generates a dry airflow

with dew point ranging from 0~100C,

and ensures the surrounding air of mould remaining in a low

dewpoint temperature. It provides constant low dewpoint

surrounding air to the mould surface all year round without

being influenced by the change of seasons.