|

|

VS600 Semi-Automatic PET Stretch Blow Molding MachineH.S.Code: 8477300000 |

|

|

|

Specification |

| Model |

|

General |

Heater Type |

|

Infrared |

|

| Capacity |

BPH |

0.5L, 900BPH

1.0L, 850BPH

1.5L, 800BPH

5.0L, 600BPH |

0.5L, 800BPH

1.0L, 750BPH

1.5L, 700BPH

5.0L, 500BPH

10.0L, 400BPH |

| Bottle Vol. |

L |

0.1 ~ 6.0 |

0.1 ~ 10.0 |

| Cavity |

|

1 |

|

| Max. Bottle Dia. |

mm |

180 |

210 |

| Neck Diameter |

mm |

20 ~ 120 |

20 ~ 55 |

| Max. Bottle Height |

mm |

350 |

430 |

|

Clamping Unit |

Clamping Force |

KN |

150 |

|

| Platen Stroke |

mm |

210 |

230 |

| Distance between Tie-bars |

mm |

544x224 |

580x260 |

| Mold Thickness |

mm |

260 (Fixed) |

|

|

Air / Power |

Driving Pressure |

Bar |

8 (Stretch & Blow)

+ 4 (Others) |

|

| Driving Air Consumption |

m3/min. |

0.6 |

0.8 |

| Blowing Pressure |

Bar |

20 ~ 30 |

|

| Blowing Air Consumption |

m3/min. |

5.0L: 1.1m3/min.;

1.5L: 0.6m3/min.;

0.5L: 0.35m3/min. |

|

| Heater Power |

kW |

30 |

40 |

|

Weight |

Machine Weight (Heater Built-in) |

kg |

1500 |

2000 |

|

Dimension |

Machine Dim. (Heater Built-in) |

m |

2.0x1.2x1.9 |

2.5x1.5x2.0 |

|

Interface |

Air Inlet |

|

Blowing: 3/4" (outer thread);

Driving: 1/2" (outer thread) |

|

| Water Inlet |

|

3/4" |

|

|

Others |

No. of Preform Seat |

Pcs |

26 |

44 |

|

Delivery Time |

60 Days |

|

|

Payment Term |

30% T/T advance as deposit, balance 70% by L/C at sight. |

|

|

Design Feature

- Higher Output (70% higher in average)

600BPH vs 200~250BPH for 5.0L bottle;

900BPH vs 400~600BPH for 0.5L bottle.

- Much More Safety, and Easier Operation

No need to insert heated preforms (hot &

difficult!) into blow mold by hand (dangerous!) or

take molded bottles out of blow mold (dangerous!).

- Less Dependence on Operator, Steady

Production

What the operator needs to do is feed cold preforms only

(before heating). Once

time setting is fixed, machine will continue production

independently at fixed output.

- Wider Application, Neck Range:

dia.20~120mm, Volume Range: 100ml~5000ml

With one machine, you can produce almost all kinds of common PET

bottles.

- Less Mold Cost

As VS600 works single cavity blow mold. The mold cost is

relatively lower than previous 2 cavity blow mold.

|

More ...

|

Toggle Clamping |

|

5-Point Double

Toggle Clamping device in optimized design with high clamping

force, fast speed and long life span. |

|

Up-sideward Cover |

|

|

All upper covers can be lifted up-sideward when

doing services to avoid mess, save space and keep site

organized. |

|

FESTO Throughout |

|

FESTO valves and cylinders. |

|

MITSUBISHI PLC |

|

With internal memory for 10 molds. |

|

MITSUBISHI Touch

LCD |

|

Friendly interface for time settings and voltage

settings. |

|

Sliding Preform

Seat |

|

Sliding preform seats carry preforms

precisely and smoothly. |

|

Bottle Eject

Robot |

|

Automatic bottle eject ensure more safety for

operator. |

|

|

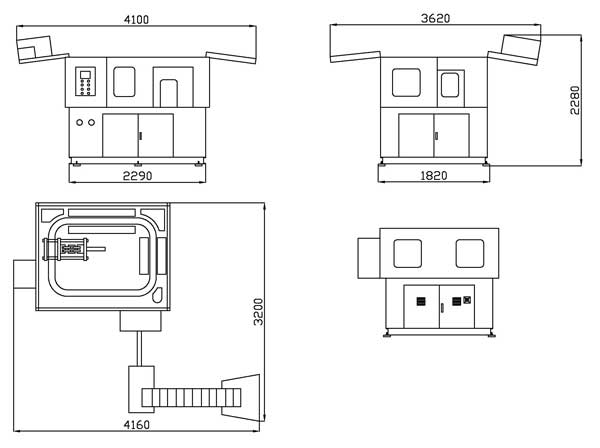

Layout

|

|

|

Plastics Machinery

Plastics Machinery PET Stretch Blow Molding Machine

PET Stretch Blow Molding Machine